The new SURELOK III is designed for all clinching applications and is faster,

smoother, quieter and uses less air than ever before. Our stainless-steel ready

machine offers a no hassle 2-minute changeover for efficient operation and

production.

Description

25” throat

Stainless steel ready with simple punch and die changeover

Clinches material with 5 tons of force smoothly and efficiently using only

90psi shop air.

Tooling adapters designed for sheet metal work that needs a 5-ton press.

Adjustable 2 1/2” stroke

Convenient adjustment for accuracy and safety

Self-Piercing Rivet kit is available for any SURELOK III to join aluminum

composite materials, TPO and PVC coatings. No predrilled holes required.

Features & Options

STANDARD FEATURES:

Throat 25″ Choose the depth of frame behind punch

Round Punch Comes with 1 punch, 3 Dies, Punch Stripper, and Die Collar

Close reach lower arm Clinch in tight areas – also great for pipes

2 piece die holder and insert Fast to change and easy to clean

Adjustable 2 1/2″ stroke Adjust open height to minimize pinch point

“Intelligent” Safety stroke Reduces pinch point to less than 1/4″ (6.4mm) even with 2 1/2″ (64mm) stroke.

High speed control 1 touch operation with increased speed & reliability – includes pressure sensing circuit.

Laser pointer Shows where clinch will be made – easy to use – meets all regulations for laser pointers.

Air Filter / Regulator / Shutoff Nothing to add – just plug your airline into the shut off valve

Extended Warranty Standard warranty is 3 years (punches and dies excluded).

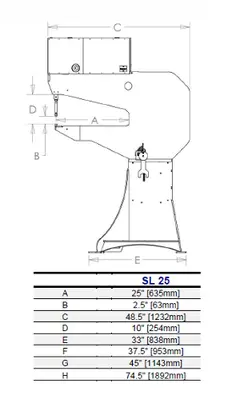

SURELOK III SPECIFICATIONS:

Press Design: 3” Thick (76mm) steel C-frame.

Rigid steel frame = longer tool life

Features: APU pneumatic power unit.

Regulator, Shut-off valve

Foot pedal operated

Stroke: 2 1/2-inches (63mm) max. (adjustable) “Intelligent” safety stroke for greater operator safety.

Throat: 25” (635mm)

Work Height: 45-inch (1143mm)

Upper Tooling: Round or Rectangular ready

Close tooling access allows for more applications.

Simple adjustments to suit material thickness.

Lower Tooling: Die insert on a hardened die plate with

a hardened protection collar.

Capacity: MAX: 2 ply .075” (1.9mm) mild steel.

MIN: 2 ply .010” (.25mm) mild steel.

MAX: 2 ply .050” (1.25mm) Stainless.

MIN: 2 ply .010” (.25mm) Stainless.

(Requires Rectangular tooling for stainless)

Cycle speed: 60-80 cycles/minute (standard)

Up to 150 cycles/minute with options

Air Requirements: 80psi to 100psi (5.4 - 6.8 Bar)

100psi (6.8 Bar) (recommended)

Approx .2 cu ft (.0056 cu m) free air per cycle.

2 HP (1.5 kW) @ 60 clinches per min.

Weight: SL 25: 1300 lb. (591kg)

We use cookies to improve your experience. Privacy Policy.