We are pleased to offer the following revised quotation for your review and consideration:

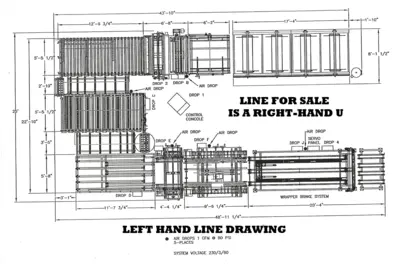

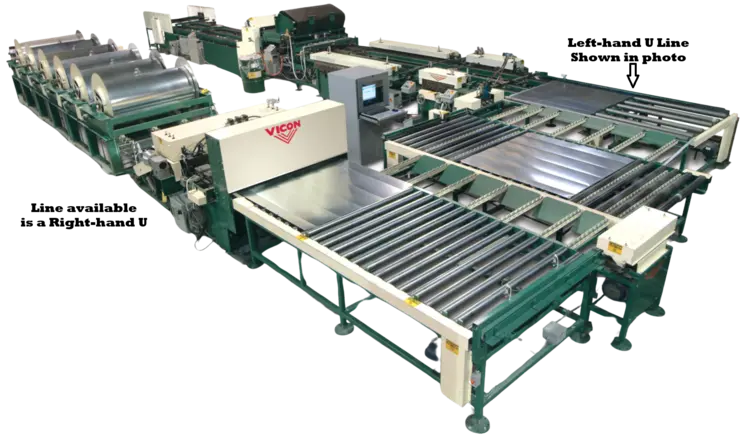

One (1) FULL TDF Vicon Right-Hand U COIL LINE equipped with Model 54C-G four (4) position underfed Coil Cradle with the following specifications:

Number of Stations:……………………………………………………..4

Maximum Coil Weight:............................................ 12,000 lb. per Station

Maximum Coil Width: .......................................................................... 60”

Maximum Coil O.D.: ............................................................................ 42”

Coil I.D.: ................................................................................................ 20”

Unit designed with pneumatic “backup” wheels at each coil station for positive feed up of each coil and safe band removal on new coils. Roller track guiding system provided to guide the end of the desired coil up to the infeed guide ramp on the duct blanking system. Coils will be spooled on Vicon's Coil Drum Assemblies.

Includes Vicon's Duct Line Express Model V-60-16-N Automatic Rectangular Duct Blanking System. System includes: Computer controlled Servo driven four (4) roll straightener with 4” diameter heavy duty straightening rolls and pinch feed rolls 18 gauge beading station to provide beading per SMACNA standards. Includes five (5) beading rings.

Hydraulic notching unit with two (2) combination “V” dies and two (2) combination “Lock” dies providing both TDX and S & Drive Cleat notching. Located between the straightener and shear. Handwheel adjustment for variations on notch depth and/or coil width. Air cylinders mounted on “V” dies for fast change over from TDX to S & Drive notching.

Dual cylinder hydraulically actuated shear with 16 gauge mild steel

capacity. Four (4) sided shear blades made of D-2 tool steel.

7.5 HP Hydraulic Power Unit

Vicon's computer control system with single point entry for all controlled line functions. Unit capable of controlling additional Vicon automatic duct fabrication components.

With a Length tolerance of ± 1/32”

Equipped with Vicon's Model HP-5 Hydraulic Tie Rod/Damper Hole Punch Unit. Designed to provide tie rod holes per SMACNA standards on center and ends as required on each leg of duct. Unit utilizes the existing hydraulic power unit and comes complete with all necessary valves, hoses, etc. Unit is installed between the straightener and the notchers on the Blanking Unit.

Line is equipped with Vicon's Model V-510-LS Lockseam System with roll form units to form Pittsburgh Lock. Maximum capacity of 18 gauge mild & 20-gauge Pittsburgh Locks.

Option 2: One (1) 5 gallon sealant system with one (1) automatic gun to apply duct sealant to the female leg Pittsburgh lock.

Line includes Vicon's Model V-510-90 Transfer and Feed Table. Automatic transfer and feed table to accept blanks from the Lockseam System and feed the cleat edge former.

Equipped with Vicon's V-CEF-DH Dual Head Cleat Edge Former, which forms Cleat Edge on short leg(s) of duct. Minimum cleat edge leg length is 4”.

Equipped with Vicon's Model V-TDX-DH-5 Dual Head TDX Rollformer, forming the TDF/TDX flange which includes two (2) sets of sixteen (16) rollform station tooling to form the rolled under safest flange in the industry on two (2) ends of duct sections. 18 –26 ga. Capacity. The flanges made on this machine are precise duplications of the industry standard TDF Flange.

Equipped with Vicon's Model V-510-DD Liner Unit. Liner system will automatically decoil, cut-to-length and apply insulation to the duct with adhesive and fasteners

The following specifications shall apply: 44”, 48”, 56”, and 60” duct liner

- Heavy duty shear blade

- Airless glue extrusion system and Pin Spotter

- Pin placement is selected by the computer control system

Equipped with Duro-Dyne's Five (5) Multi Head Pin Spotter

Equipped with Vicon's Model V-516B-FW Full Wrap Automatic Brake System. System includes infeed table, 5’ hydraulic brake, outfeed conveyor, Front Gauge System controlled by the computer control system. System is designed to form L, U, or Full wrap duct. Includes precision high speed Servo positioning positive feed system.

- 6” x 6” minimum size capacity (unlined)

- Maximum capacity of 120” wrap perimeter

Delivery: October 2025

We use cookies to improve your experience. Privacy Policy.