• 4' x 8' Cutting Area, Single Piece, Unitized Design.

• Direct Drive Rack & Pinion. (NO BELTS OR PULLEYS)

• Hybrid Micro Step Drives

• Planetary Gear Boxes

• Full Table Capacity of 5/8 inch Plate

• Positioning Accuracy: +/- 0.012 inch

• Max Traverse Speed: 1,400 inches per minute

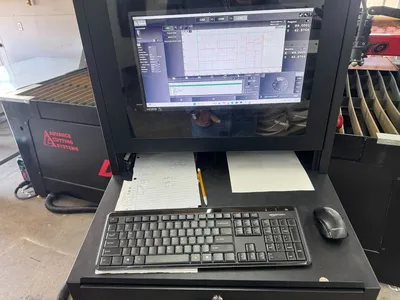

ADVANCE V10-P CNC Cutting Table Controller

- Windows 10 PC-Based Machine Tool Controller

- 20” TFT Display Operator Interface

- USB Interface, Four USB 2.0

- Operator Controls:

- Industrial Sealed Steel Construction

- Waterproof Keyboard and Mouse

- Start, stop, manual, forward/reverse on path, torch up/down, & E-Stop

- Automatic Corner & Plate Alignment

- Remote Machine Service and Diagnostics

- All Hypertherm Plasma Cut Charts and Feed Rates

- Consumable Tracking & Install Screen

RemoteHelp

• Remote Help is an internet based tool that allows the table manufacturer to be virtually in your factory within minutes. CNC and cutting table diagnosis and repair can often be accomplished without an on-site visit. This means that cutting tables can be up and running quickly and without costly travel and wait time.

• Remote Help features include: Fast and secure connectivity; Safe remote access to the CNC to

view and modify setups; Secure and rapid transfer of files; Free access for all parties.

Tooling Configuration: Hypertherm POWERMAX-45 Plasma Unit

• 45 Amps (Max)

• 3/8-inch Production Capacity

• Newest Hypertherm Cutting Technology

For additional information please call us at 800-753-0393 or email norm@threeriversmachinery.com

We use cookies to improve your experience. Privacy Policy.