Shear Blade MAINTENANCE

Shear blades are precision tools. A great deal of expertise is given to the design and manufacturing of the tool. Experienced engineers carefully design the tools so that they reflect the requirements of the machines they will be used on. Highly trained and experienced manufacturing personnel turn the engineers' specifications into the finished product. Even once the shear blades are completed, they are handled and packaged in a manner which ensures the shear blades are delivered to the end user in perfect condition.

SHEAR BLADE STORAGE

When not in use, the shear blades should be kept in their wooden shipping containers. They should then be stored on a flat surface with no heavy objects placed upon them. Heavy objects placed on top of the stored shear blades may cause even a very slight bow which may be reflected in the cutting process. It is also important when the shear blades are stored that all surfaces' blades be covered by oil. This will help prevent rust as any pitting caused by the rust will often become a focal point for cracking.

SHEAR BLADE HANDELING

It must be remembered that although a shear blade is a very strong tool, it must be handled with extreme caution. Due to the shear blade being hardened to approximately 60Rc, it must be considered as a very brittle tool. Dropping it on a hard surface can literally cause it to break. Also, the cutting edges are very sharp and can easily be shipped if proper care is not taken.

SHEAR BLADE LEVELING

For the most part, machine tools are designed to be operated in a level configuration. The mass of the cutting head on a shear machine is such that any out of level condition will cause the cutting head to try and deflect from the vertical cutting plane. Number one, this can affect the quality of the cut. Secondly, any out of level condition will put undue stress on the bearings. If this condition exists for an extended period of time, it may cause major damage.

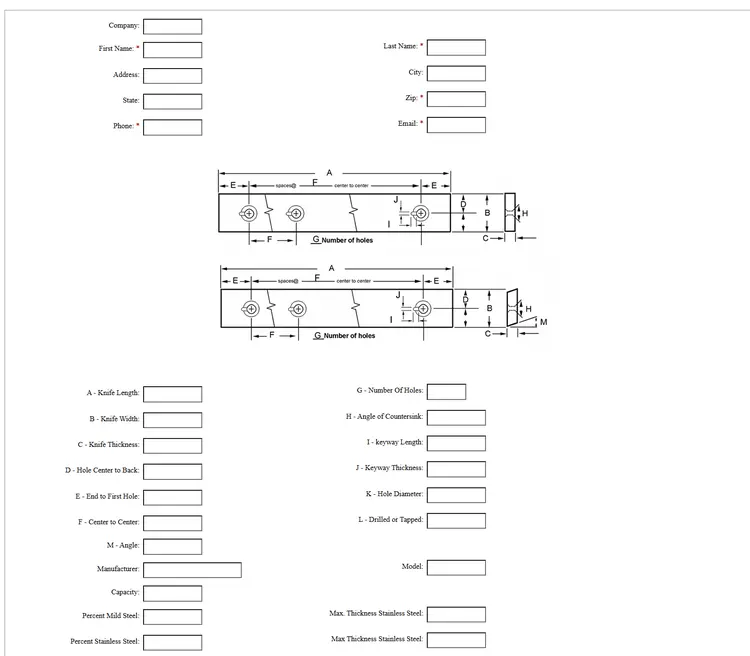

TO ORDER NEW SHEAR BLADES CLICK THE PHOTO BELOW, PRINT AND SCAN THEN EMAIL to NORM@THREERIVERSMACHINERY.COM or call 412-921-2800 or FAX SHEET TO 412-921-2801, thank you!

We use cookies to improve your experience. Privacy Policy.