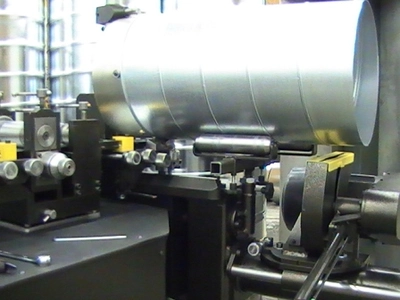

Sidewinder Spiral Pipe Machine

The SideWinder Spiral Pipe Machine has one of the most compact foot prints in the industry and could easily be taken to a job site! Easy set-up means minimal delay when changing from one diameter to another.

No flood coolant. No mess on your shop floor- outside of pipe remains dry.

Our unique forming process reduces scrap because we form outside the head.

Inside diameter is always the same regardless of gauge being formed.

New improved gaurding ensures operator safety

Our patent pending seam lock ensures consistent inside diameters from end to end.

Lower cost

The installation of spiral ductwork — including labor, transportation, warehousing, and packaging — can cost up to 50% less than traditional rectangular duct. Because of its strength and rigidity, spiral duct requires fewer supporting components and fewer tools to install. It is typically made of a lighter material than rectangular duct, which makes installation easier; in fact, it can often be installed by just one or two people rather than a whole team.

Higher efficiency

Air leakage at duct joints is a common problem for traditional rectangular ductwork, which leads to energy loss and poor system efficiency. Spiral duct systems, however, typically meet or exceed industry air-leakage standards. With less leakage, the cost of heating, cooling, and filtering conditioned air is much lower and indoor air quality is a lot higher. The spiral design of the system keeps internal air pressure equal, allowing the air to flow evenly and efficiently.

Less noise

Noise breakout is another issue that is common with rectangular ductwork. The design of the rectangular system causes air to move around sharp edges, dampers, and turning vanes. This obstruction contributes to noisy turbulence; however, spiral ducts have smoother edges that eliminate reverberation, creating less noise.

We use cookies to improve your experience. Privacy Policy.