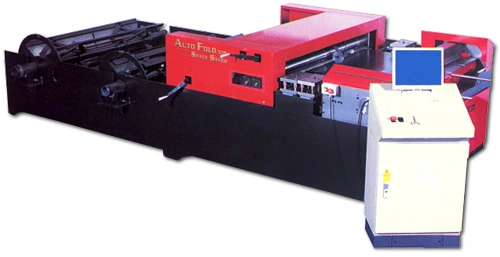

Advantages:

Compact Design: Single-piece Machine Requiring Minimum Shop Floor Space

Coil Capacity: Built-in Two-In-One Coil Holder & Two Ea. 10,000 Lb. Expanding

Coil Mandrels for 19in. to 25in. Coil I.D.’s.

Production Functions: Leveling, Beading, End & Vee Notching, and Folding &

Shearing. Produces Duct In the Flat, In “L’s”, “U’s”, or “Fully Folded, 4-Sided”

In 4-ft, Or 5-ft. Lengths

Save Labor & Material: One-Man Operation, “Zero Waste” Job-to-Job. And

Serves As Cut-To-Length line To Produce Exact Required Sheet lengths For

Fittings To Be Cut on Plasma Table

AF-516 SS Standard Features:

• 2ea 10,000 LB Capacity Coil Mandrels • Coil Range 19″ ID or 27″ ID

• Adjustable Leveler • Adjustable Beader

(Maximum 18ga Capacity)

• 2ea Adjustable “V” Notchers for

S & D and TDF/C • 2ea Adjustable Corner Notchers for

S & D and TDF/C

• 5′ 16ga Capacity Shear • 5′ 16ga Capacity Folder

• Material Jam Detector • CNC Controller with USB Port and

Color LCD Screen

• Base machine is one piece

(14′ L x 6’6″ W)

AF-516 SS Options:

• Additional Coils • Power Coil Drive (CDA)

• Automatic Female Side Eject

Pittsburgh Rollformer • Gague Counter

• Down Load from Plasma Cutting

Software

The Space Saver can produce the following:

Flat cut to length blanks with or without beads

Flat cut to length duct with notches (1,2,3 or 4 piece)

“L” Sections with or without notches

“U” Sections with or without notches

Fully Wrapped Duct Sections with or without notches

Produces Male Pittsburgh

We use cookies to improve your experience. Privacy Policy.